The Last 11 Weeks

The latest prototype with on-board audio has been hugely popular, much more so than I expected. I thought there would be demand for about five units a week, but over the last month it has been more like fifteen. I have been a little overwhelmed with the interest and at times have had a few issues with component supply. Many components have a lead time of three weeks or more, and I failed to order enough of them. I think I have sorted out supply for at least the next two months unless demand increases again.

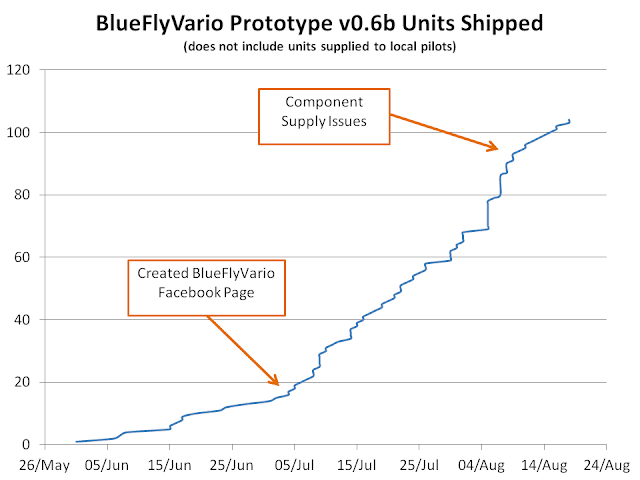

The graph below shows how the project has grown by plotting web based orders since the prototype was released on 31 May. In addition to the 100 or so units graphed below I have supplied about 20 to local pilots and non web based orders. There was a significant increase in demand just after I created the Facebook page to help spread the word, and there has been a small slowdown while I have had some component supply issues. These are now fixed and I should be ready to fulfill interest over the next few months.

Production Streamlining

I am still assembling each vario by hand. I have to say that assembling, programming, debugging, testing, packing and shipping 120 mini varios at home is not a task to be embarked on without due consideration. I have considered various options for getting someone else to do assembly and shipping. The PCB assembly part is the most obvious, but it only represents about 30% of the time to make each vario and I think outsourcing it would be more hassle than it is worth, and more expensive. I have become much more efficient at the overall process and now it takes me about half as much time for each vario as it did when I started.

I am lucky that this year I have little work in the evenings or on the weekends and have time to continue to pursue this hobby. Also, for the last eight months I have not been able to fly as I continue to recover from being broken in an accident in December last year. I should be able to get back in the air in the coming weeks and am looking forward to actually testing one of the varios myself. This will mean less time to make and develop varios if the weather cooperates, but thankfully for the project (and unfortunately for my flying prospects) the weather often offers non-flying days.

Further Development

The current version 0.6b prototype is proving stable and I intend to continue producing it for at least the next few months. Only one person has reported a error with the hardware (the switch broke) from over 100 varios in use. I have a few ideas for the next hardware version. Most of these are about making them easier to assemble. I have been very focused on hardware production and development, perhaps when I get back in the air I will focus more on making the app better.

The latest prototype with on-board audio has been hugely popular, much more so than I expected. I thought there would be demand for about five units a week, but over the last month it has been more like fifteen. I have been a little overwhelmed with the interest and at times have had a few issues with component supply. Many components have a lead time of three weeks or more, and I failed to order enough of them. I think I have sorted out supply for at least the next two months unless demand increases again.

The graph below shows how the project has grown by plotting web based orders since the prototype was released on 31 May. In addition to the 100 or so units graphed below I have supplied about 20 to local pilots and non web based orders. There was a significant increase in demand just after I created the Facebook page to help spread the word, and there has been a small slowdown while I have had some component supply issues. These are now fixed and I should be ready to fulfill interest over the next few months.

Production Streamlining

I am still assembling each vario by hand. I have to say that assembling, programming, debugging, testing, packing and shipping 120 mini varios at home is not a task to be embarked on without due consideration. I have considered various options for getting someone else to do assembly and shipping. The PCB assembly part is the most obvious, but it only represents about 30% of the time to make each vario and I think outsourcing it would be more hassle than it is worth, and more expensive. I have become much more efficient at the overall process and now it takes me about half as much time for each vario as it did when I started.

I am lucky that this year I have little work in the evenings or on the weekends and have time to continue to pursue this hobby. Also, for the last eight months I have not been able to fly as I continue to recover from being broken in an accident in December last year. I should be able to get back in the air in the coming weeks and am looking forward to actually testing one of the varios myself. This will mean less time to make and develop varios if the weather cooperates, but thankfully for the project (and unfortunately for my flying prospects) the weather often offers non-flying days.

Further Development

The current version 0.6b prototype is proving stable and I intend to continue producing it for at least the next few months. Only one person has reported a error with the hardware (the switch broke) from over 100 varios in use. I have a few ideas for the next hardware version. Most of these are about making them easier to assemble. I have been very focused on hardware production and development, perhaps when I get back in the air I will focus more on making the app better.